Feedback on an EDITAG Industries customer case.

One of our customers manufactures machines in a workshop with several dozen workstations.

There are about fifty machines in production for the main assembly part and about as many in intermediate stocks awaiting customer customization, quality test, after-sales service or simply in stock of new machines ready to go. shipping.

The machines are bulky, difficult to handle. They are stored by the operators with simple rules. However, finding a machine to complete your treatment takes a long time.

The direct cost of this lost time is significant and we must also consider the costs incurred such as production stoppages, delivery delays, etc.

The EDITAG WIP solution

Our track and trace solution EDITAG Industries (RTLS) onsists of placing one of our IIoT sensors, mOOnTAG, on each machine. The hyperlocation functions by zone make it possible to know the position of each machine in real time and considerably reduce search times.

The solution also makes it possible to know precisely the processing times on each workstation, to automatically update the production kanban board and to have a perfect and real-time view of the production.

Return on investment

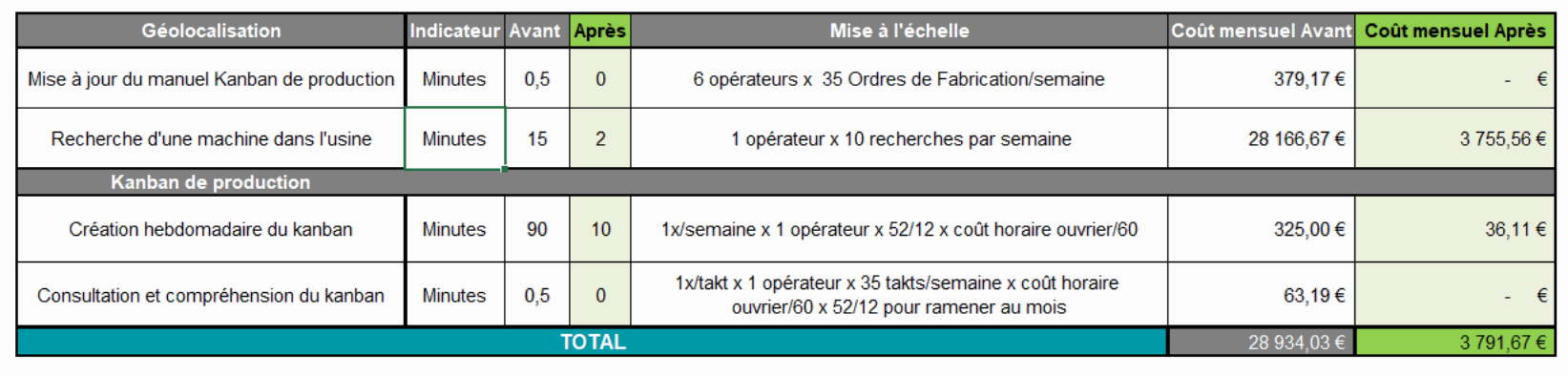

We measured the gains and calculated the ROI time:

The return on investment of the EDITAG WIP solution is spectacular, it is 3 months!

| ROI according to deployment budget EDITAG Industries | 2,98 months |

Des effets de bord positifs supplémentaires

Other sources of savings have also been identified, such as the reduction in the fleet of handling units, thereby limiting downtime. MOOnTAGs with integrated screen allow all production orders to be deleted in paper version by eliminating errors.

An example of an IIoT deployment with a rapid and proven ROI!