What is behind this term “all-in-one”? What are the benefits that can be expected?

Whether it is our IoT sensors, our software controller or the communication protocols used, all the components in our range are designed to allow manufacturers to extend their use of the solution.

The all-in-one for a variety of uses

Before talking about the technical aspect of the all-in-one, it is important to recall the evolutionary aspect of the EDITAG Industries range in terms of uses.

Concrete example with an automobile manufacturer. We have deployed our solution on the assembly lines Pick-To-Light. The system is used to help operators prepare orders or kits of parts to be assembled to supply production areas.

The Pick-To-Light IoT is a proven industrial solution, suitable for “on-premise” or “cloud” architectures, capable of supporting the high production rates and high availability requirements imposed by the automotive industry in particular.

In addition to Pick-To-Light, the solution integrates other features such as location (zoning), l’Andon and also applies for Put-To-Light.

From a deployed solution, uses evolve and meet other field needs.

The benefits of the all-in-one IoT sensor

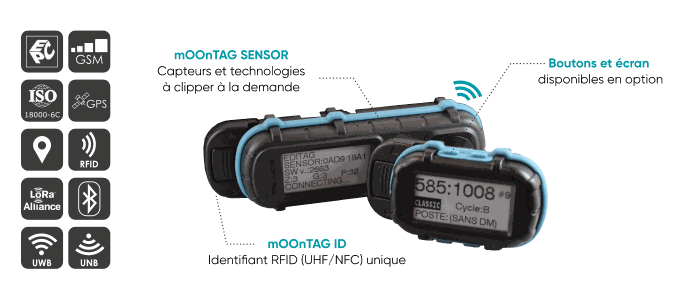

All EDITAG IoT sensors are designed on the same principle: lean, connected, hybrid and modular.

They integrate different technologies and functionalities to expand their use according to user needs.

Thus the same sensor can meet different uses, as in the example of Pick-To-Light.

Interface with third-party systems

When several systems are interconnected and exchange data, the question must be asked of their long-term compatibility. Each publisher has its own pace of updating, each publisher pursues its own goals … Maintaining connections with third-party applications is not necessarily a common goal.

Our LOKEOS software controller acts as an all-in-one unifying system for data acquisition. It propagates them through a simple digital interface to all business applications that need to be fed by field data (ERP, MES, BI, etc.)

LOKEOS ensures the consistency of data in the various information systems in real time.

Guarantee operational maintenance

Multiplying the systems also means multiplying the suppliers, the potential bugs, the obsolescence of the architectures and the maintenance contracts. If something goes wrong, it’s common to end up with vendors passing the buck endlessly.

With an all-in-one solution, operational integrity is preserved. The data collected is available and isolated from dysfunctions.

The adoption of innovation and training: the unifying effect

We have manufactured our systems according to the reality on the ground and the constraints of the operators. LOKEOS is a user-friendly tool, the use of the sensors is intuitive and does not require any training. Everything is done to facilitate the integration of solutions into existing processes.

However, operators must adopt the new tools at their disposal.

The all-in-one also plays a role in accepting solutions. Integrating new features and extending uses from a single solution is a considerable advantage for field teams. They then focus on their missions and not on the use of complex and multiplied systems.

How about the costs?

Last but certainly not least! several systems = several licenses = several support contracts, VS maintenance. a license and a contract.

An all-in-one solution is obviously cheaper to purchase but also has a much lower TCO (Total cost of ownership).